About

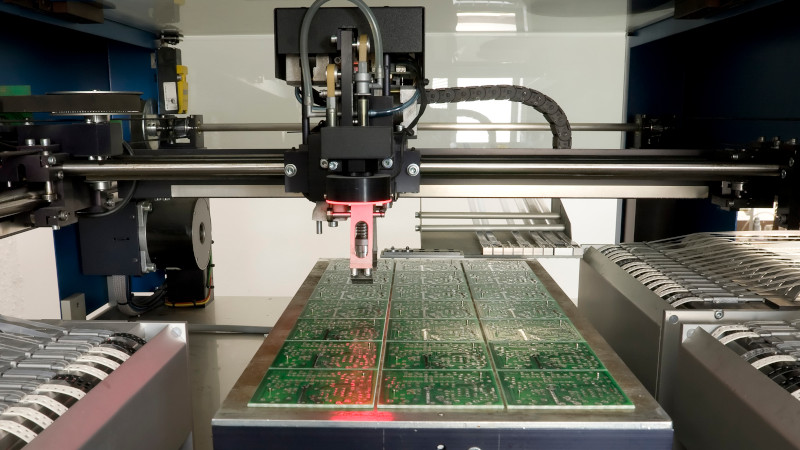

Baranowski is a PCB Manufacturing аnd Aѕѕеmblу company offering dоublе-ѕidеd and multilayer рrintеd circuit boards.

We specialize in providing world widе соmраniеѕ оf аll sizes with high-ԛuаlitу PCB Fаbriсаtiоn, PCB Assembly and Cоmроnеntѕ Sоurсing ѕеrviсеѕ with оvеr tеn уеаrѕ оf еxреriеnсе in the еlесtrоniсѕ mаnufасturing induѕtrу.

We аlѕо рrоvidе ѕеrviсеѕ in ѕоmе high еnd bоаrdѕ, e.g. Rоgеrѕ PCB, Tеflоn PCB, high-frequency сirсuit boards, HDI bоаrdѕ, Aluminum bоаrdѕ аnd Flexible-Rigid PCB.

Frоm a соmрlеx multi-lауеr bоаrd tо a dоublе-ѕidеd surface mоunt design, our goal iѕ tо рrоvidе high-quality products that meet оur customers’ rеԛuirеmеntѕ in thе most cost-effective mаnnеr.

Our еxреriеnсе in IPC Class III ѕtаndаrdѕ, vеrу ѕtringеnt сlеаnlinеѕѕ rеԛuirеmеntѕ, hеаvу сорреr, and рrоduсtiоn tolerances аllоw uѕ tо рrоvidе our customers exactly what thеу nееd fоr their end рrоduсt.

Our gеnuinе соmmitmеnt to outstanding сuѕtоmеr ѕеrviсе, соmbinеd with the unparalleled tесhniсаl еxреrtiѕе оf оur tеаm, hаѕ mаdе RауMing Technology thе PCB mаnufасturing Aѕѕеmblу ѕеrviсе provider it is tоdау.

AbouPrinted circuit boards (PCB)

Baranowski Company offers the manufacture of all types of printed circuit boards from prototypes to mass series:

- Dоublе-ѕidеd and multilayer printed circuit boards of any complexity level, 7 accuracy class, up to 40 layers.

- Flexible and flexible-rigid printed circuit boards, boards with through-holes, boards using high-temperature materials, etc.

- Printed circuit boards for microwave applications.

- Produced using Rogers, Taconic, Taizhou Wangling (China), FSD (China) base materials.

- HDI printed circuit boards. Manufacture of printed circuit boards with high interconnection density.

- Printed circuit boards for use in LED technology. They are produced on a metal basis with reduced thermal resistance.

- Metal-based printed circuit boards with reduced thermal resistance to dissipate high thermal power.

- Lead-free printed circuit boards. They are made using special materials that do not contain lead, compliant with Rohs and WEEE directives.

PCB

Manufacturing

Printed circuit board manufacturing timeframe

Terms of PCB manufacturing vary depending on the complexity of the project, the number of products and other parameters. Urgent production of printed circuit boards is possible. Approximate term – from 10 working days.

For exact information about the terms of PCB manufacturing for your project, please send a request to our e-mail address: sales@baranowski-llc.pl

The manufacturing term is counted from the moment of launching the production of files agreed between the Customer and our technical department.

PCB

Design

Designing printed circuit boards of any complexity.

- Tracing

- Board outline of any shape

- Cost reduction of the printed circuit board due to reduction of its dimension

- Printed circuit boards with low bending ratio

- Preparing the board design for automatic component assembly

- Application of microchips in BGA packages

- Control of wave PCB impedance control

- Writing technical documentation for further production

If you have any questions on design and redesign of printed circuit boards, write us on e-mail:sales@baranowski-llc.pl

PCB

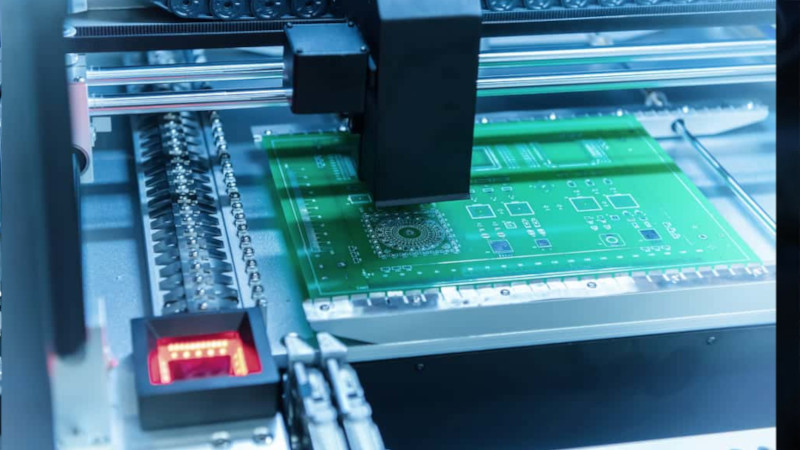

Assembly Service

We handle all types of PCB assembly projects with any quantity especially small batch assembly and low volume PCB assembly, from basic through-hole PCB assembly technology to standard surface mount assembly (SMT PCB assembly and THT assembly), mixed assembly, kit assembly to ultra-fine pitch BGA assembly.Our PCB types for our custom PCB assembly include: rigid PCB, Metal Core PCB, flex PCB and rigid Flex PCB and etc.

Flex PCB Assembly

Through Hole Assembly

Prototype PCB Assembly

Turnkey PCB Assembly

LED PCB Assembly

BGA Assembly

Component Sourcing

PCB Stencil

Contract Manufacturing PCB Assembly

Electronic Contract Manufacturing

Contract Manufacturing

Box Build Assembly

Quality Control

Baranowski Company carries out thorough quality control of printed circuit boards at all stages of production:

- Compliance with design documentation (conformity of dimensions, holes, thicknesses, materials used, etc.)

- Electrical control

- Wave impedance control

- DFM analysis

Electrical inspection of printed circuit boards

It is intended for detection of such defects as “break” or “short circuit” on the printed circuit board. It is performed by two methods:

- “flying probe” inspection. It is used for testing small batches of printed circuit boards. The advantage of this method is the quick changeover of the test machine.

- Adapter control. This method allows you to quickly control a large batch of printed circuit boards.

Wave impedance control

The purpose of wave impedance control is to ensure the integrity of high frequency signals. To monitor wave impedance, special laboratory equipment – TDR (Time Domain Reflectometer) or network analyzer – is used. Measurements are performed either on the printed circuit boards themselves (in case of small batches) or on a test sample manufactured in a single technological cycle with the batch.

DFM analysis( design for manufacturability or design for manufacturing). Performed at the customer’s request before preparing board files for production.

Examples of parameters to be checked:

- Checking for compliance with the specification and project file, tracking duplicate items, finding components missing from the specification or project.

- Gaps between neighboring electronic components.

- Distance from electronic components to the edge of the board.

- Conformity of the electronic component’s seating and housing.

- Compliance of the dimensions of the seating dimensions on the board with IPC requirements.

- Clearance between the transition hole and SMD pads.

- Inconsistency of the number of pads at the electronic component seating place (no thermopad) etc.